Lumo folding stool

Physical product design

I designed and built this CNC-cut folding stool for a Furniture Design course. In designing the stool, I followed a thorough design process that included creating a user persona and moodboard, conducting market research, design and prototyping, and fabrication.

Defining a user

I began by creating a user persona and moodboard to guide my design process. My persona specified a millenial user living in the Pacific Northwest with a reasonable disposable income, an appreciation for design, and a passion for the outdoors. My user wanted a product that would increase the seating capacity of their living space while hosting guests. Given space constraints in their apartment, they sought a product that could be stored or stowed easily, when not in use.

After specifying my user and use case, I produced a moodboard. Through my moodboard, I intended to capture the underlying characteristics of my user’s aesthetic sensibility and distill their priorities. These products blur the line between classic and modern. Through quality materials, higher-end price points, and echoes of traditional craft, they communicate an heirloom-like quality. The products generally eschew plastic, instead embracing natural materials like wood, leather, and wool.

Conducting market research

I conducted market research, complining a diverse list of products that addressed the specified use case and analyzing them across both qualitative and quantitative dimensions. These products encompsed a wide spectrum of price points, ranging from $12 (from Ikea) to $3,618 (from Fritz Hansen). In addition to price, data was collected on the stools’ size, weight, folding capacity, materials, and place of manufacture. Once compiled, this data was visualized in the form of a matrix and scatter plots.

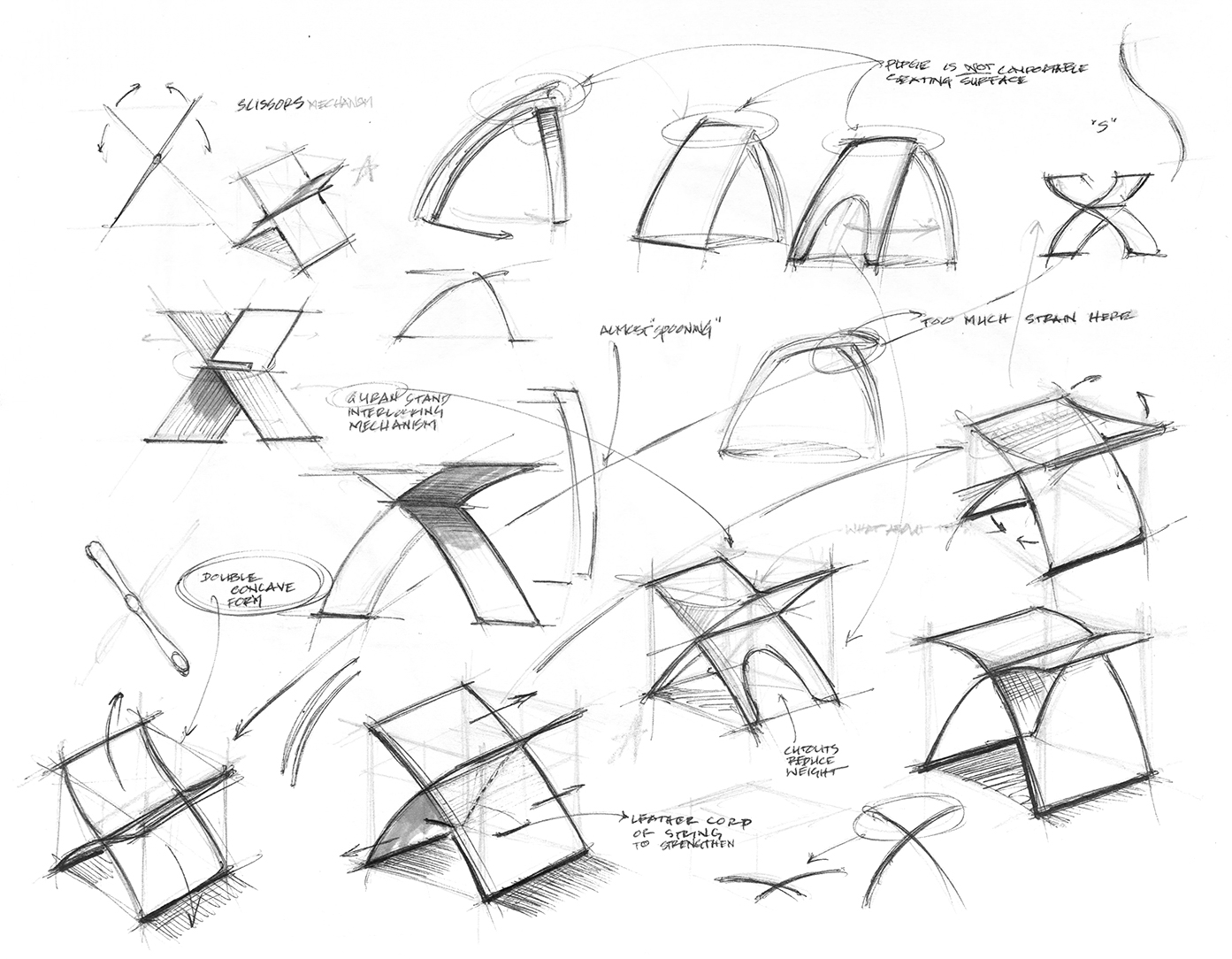

Design and prototyping

Fabrication

After finalizing my design, fabrication of the stool was completed relatively quickly. Aided by a CNC router, I was able to reliably cut 28 plywood fins in two profiles. Once cut, these fins were assembled, tapped, and connected with a steel shaft capped with stainless steel screws. After sanding and finishing, a seat made of 8 oz American leather was attached to the stool using glue and chrome-finished tacks.

Product