CANDLE HOLDER

→ Product Design

I designed and fabricated this fluted candelabra in the spring of 2024 for a Ceramic Production studio course. The design draws inspiration from George Nelson’s iconic 1947 bubble lamp collection. Nelson stretched taut plastic over wire frames to create novel forms with soft, sculptural curves. The fluted surfaces of these lamps capture ambient light, becoming art objects when illuminated by daylight.

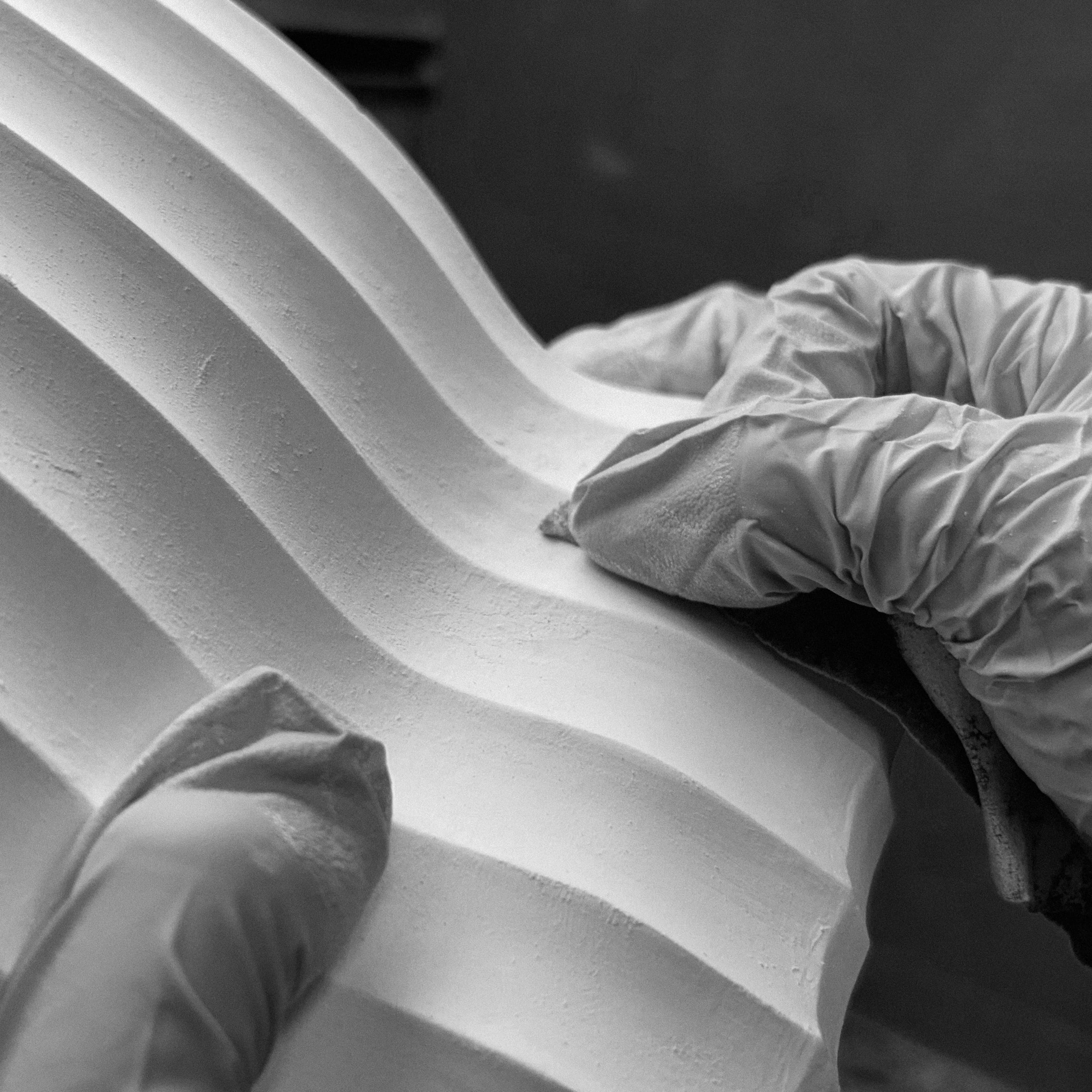

For my candelabra, I reimagined these fluted textures in ceramics, applying them to a silhouette inspired by traditional candle holders. The bottom-heavy form nods to the visual languge of mid-century modernism. In addition to catching light, the flutes provide channels for overflowing wax as it melts down the side of the candle holder.

→ Process

After selecting a design, I used scrap clay to produce a rapid prototype. While crude, this prototype helped me to refine a form factor and settle questions of proportion. With these measurements, I designed the form in Rhinoceros 3D. I 3D-printed the resulting design in ABS plastic, finishing the pattern with primer and lacquer to create a smooth surface suitable for mold-making. From this pattern, I poured a 5 part plaster mold.

The slip casting process enables the production of precise ceramic multiples with limited marginal investment. I took advantage of this process to explore various glaze finishes, experimenting with how different surface treatments interacted with light and resisted heat and wax. Of these, my favorite was an off-white matte finish that I believe complemented the object’s form-forward design.

This project was an exploration of form, texture, and functionality, bridging digital and traditional fabrication methods to create a modern interpretation of a timeless object.

→ Product